Heavy duty process pumps

Heavy-duty slurry pumps for lowest cost-per-ton pumped

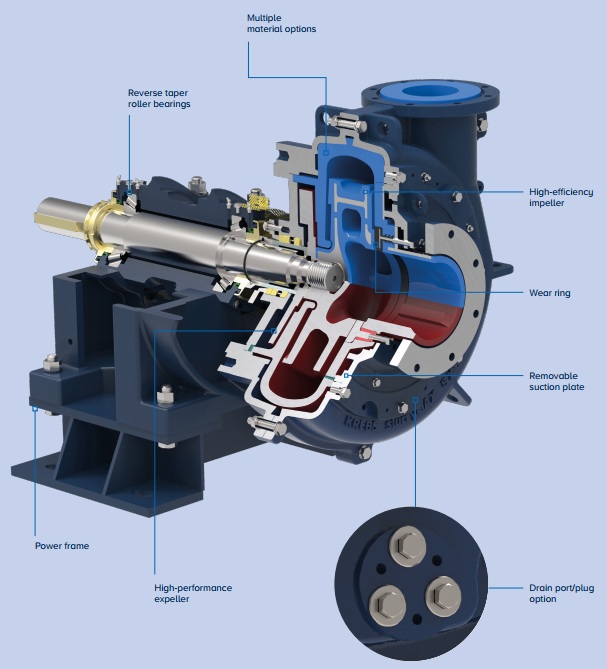

Featuring our proprietary wear ring technology, KREBS® heavy-duty pumps reduce power consumption and extend wear life when pumping abrasive slurries. These reliable workhorses are built for mineral processing applications and others that require durable and reliable performance in harsh conditions.

Key benefits our heavy-duty process pumps

■ Even and predictable wear life for wet end parts

■ Significant energy savings

■ Constant hydraulic performance

■ Highly effective centrifugal seal

■ Long-lasting bearings that cannot be over-greased

■ Multiple liner and casing materials for a wide range of applications

slurryMAX™ Optimised design

gravelMAX slurry pumps

When pumping large solids, the gravelMAX pump is your answer. A large impeller-suction side clearance prevents in-pump grinding when entering the pump, while a wide-diameter impeller and increased cutwater clearance allow solids to exit the pump.

- Pump large and abrasive solids.

- All of the benefits of our wear ring.

millMAX slurry pumps

The first pumps to feature our suction-side sealing system, the millMAX heavy-duty pump sets the standard for cost-effective slurry pumping.

- Improve mill throughput.

- All the benefits of our wear ring.

slurryMAX-XD slurry pumps

The slurryMAX-XD horizontal pump features a heavy-duty impeller and thick, steel-reinforced elastomer linings to extend wear life, enabling it to handle the most aggressive applications, including primary cyclone feed and tailings.

- Even and predictable wear life.

- Interchangeable material options.

- All of the benefits of our wear ring.

UMD mill discharge pumps

The UMD ultimate mill discharge pump is the most advanced slurry pump for mill discharge pumping applications. Its optimised hydraulic pump design delivers the highest efficiency and even wear in the most abrasive mining applications. A wide flow casing option is available for wide operational process duty points.

- Up to 10% less power consumption.

- Wide range of sizes and wear liner options.

- Symmetrical casing reduces inventory requirements.

UMD-R mill discharge pumps

The UMD-R pump is a fully rubber-lined, split-case version of the UMD mill discharge slurry pump, particularly suited for wide flow ranges and corrosive duties.

- Even and predictable wear life.

- Lowest cost-per-tonne pumped.

- All the benefits of our wear ring.

Downloads for heavy-duty pumps

Brochure: KREBS® millMAX™ pump – The original suction side sealing slurry pump

Brochure: KREBS® slurryMAX™ – Tough & versatile slurry pump

Product datasheet: KREBS® Quick Release System

vMAX™ Pumps Making sump and plant floor clean-up a breeze!

Pumping highly viscous fluids or slurries containing large solids is fraught with difficulties. KREBS® vMAX vertical cantilever slurry pumps tackle these problems, eliminating build-up at the suction inlet, leakage from the casing back, and excessive vibration.

vMAX vertical cantilever slurry pumps

An optimised hydraulic design enables the vMAX pump to handle large solids and highly viscous fluids while its bottom-only suction configuration prevents clogging. It’s ideal for typical-to-extreme clean-up sump duties and can be supplied in a tank or on a skid.

- Large solids passing size.

- No sump level control is required.

- Easy to operate, easy to maintain

vMAX-R vertical slurry pumps

The vMAX-R pump is a rubber-lined version of the vMAX pump. It was developed to handle the most difficult corrosive slurries with finer solids. The pump is adaptable to many acid and slurry temperature combinations and has multiple material options.

Explore our slurry pumping solutions

For further information, please feel free to explore our portal website: