Slurry valves

Rely on KREBS® heavy-duty slurry valves for harsh slurry applications

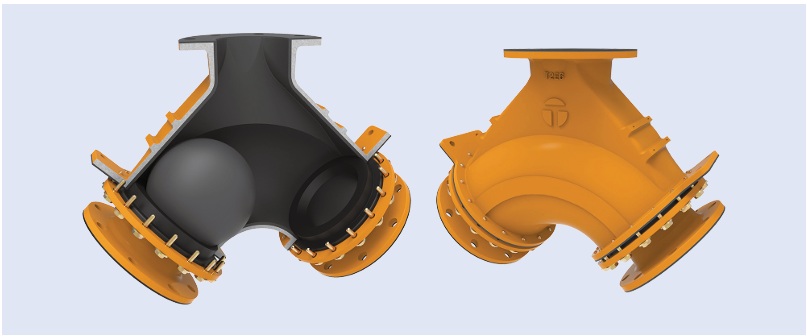

Our KREBS® heavy-duty knife gate, check, and vacuum breaker valves deliver reliable performance while reducing CAPEX and maintenance-related costs. These valves are designed specifically for mineral processing applications to handle the most abrasive of slurries.

Key benefits of slurry valves

■ Enhanced safety features on every model

■ Proven quality materials and reliability

■ Decreased downtime and faster maintenance

■ Interchangeable components reduce your inventory

■ Premium materials are supplied standard on all valves

■ Reduce maintenance and downtime

Our slurry valves

KREBS heavy-duty slurry valves are used in all mineral processing applications and across all process lines, from the comminution circuit to tailings. The comprehensive range includes full-flanged, wafer and high-pressure knife gate valves, vacuum breaker valves, and check valves.

Types of Slurry Valves including:

■ High-pressure knife gate valves: TG, TGW, TGH, TGHP,…

Maintenance & Service of Slurry Valves

Our pioneering service solutions include offsite maintenance and exchange solutions that reduce downtime and costs. We provide fully refurbished pumps, cyclones, and valves ready to replace existing equipment when needed. We’ll then take the worn part to one of our global service stations for rebuilding before returning to you to repeat the cycle. We also evaluate the worn equipment during servicing and provide recommendations to enhance service life. This ensures top-of-the-line service and reduces time onsite, mitigating the safety risks inherent to onsite maintenance.

For further information, please feel free to explore our portal website:

Heavy-duty slurry valves from FLS